Exhaust Manifold Kit

Exhaust Manifold Kit

Exhaust Manifold Kit

information to be updated

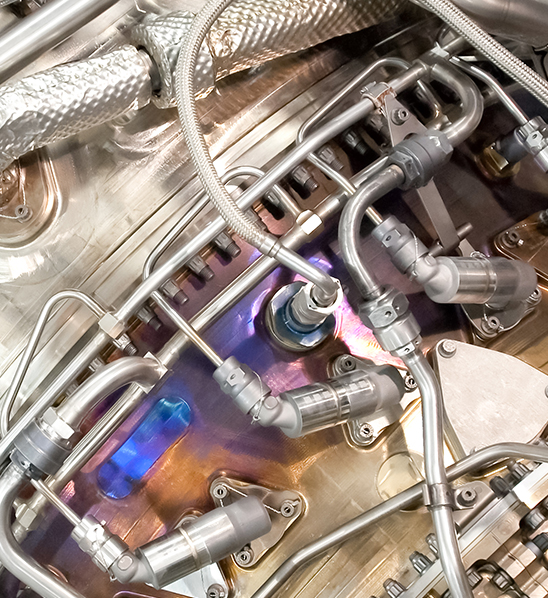

The Exhaust Manifold Kit is a critical component between the engine and the exhaust manifold. It includes a complete set of manifold bodies, bolts/nuts, washers, spacers, brackets, and (optional) accessories such as heat wrap or ceramic coating. It's designed for one-stop replacement or upgrades, eliminating secondary purchases due to missing parts. In addition to our standard product line, we also offer full-process customized solutions, from single-piece production to mass production, for a wide range of industries and applications.

Product Features

Increases exhaust flow rate and reduces backpressure

Optimized pipe cross-section and equal-length design reduce exhaust resistance, increasing engine power and torque

High-temperature and corrosion resistance

Commonly used materials include high-silicon-molybdenum (HSM) cast iron, titanium alloy, or stainless steel, offering enhanced thermal strength and crack resistance, preventing the cracking of original gray cast iron under high-temperature cycling

One-stop kit for easy installation

The kit comes complete with all accessories, including bolts, washers, and brackets, and is available pre-assembled or pre-treated. Users simply follow the instructions for installation, eliminating the time and cost of purchasing individual parts and re-commissioning.

Compatible with later modifications and tuning

Standardized threads and adjustable brackets facilitate subsequent installation of high-flow turbos, exhaust pipes, or ECU tuning, maintaining flexibility and upgradeability.

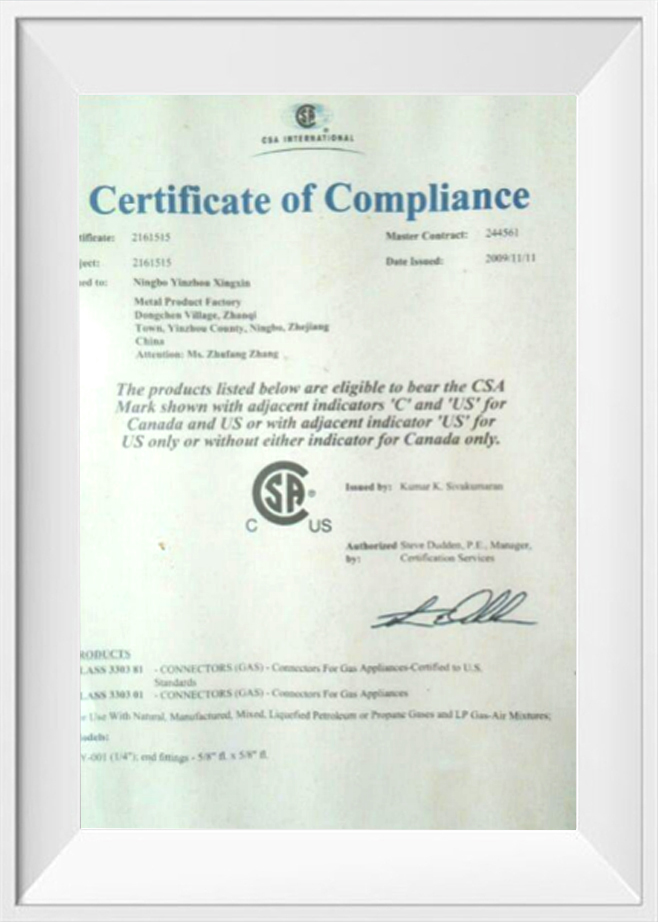

About JIATIAN

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

Is Your Diesel Engine Losing Power? A Closer Look at Fuel Delivery IssuesIf you've noticed your diesel vehicle, truck, or equipment isn't responding the way it used to, you're not alone. A gradual loss of power, a rough idle, or a sudden decrease in fuel economy can be fru...view More

Dec 15, 2025 ? Industry News

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

As a high-tech enterprise deeply engaged in the automotive pipe fitting industry, JIATIAN’s?Exhaust Manifold Kit?is a core supporting product connecting the engine and the exhaust system. The common features of this category of products are that they can realize one-stop replacement or upgrade of the exhaust system, and at the same time have core performances such as high-efficiency exhaust, resistance to extreme working conditions, and adaptability to later modifications. JIATIAN’s Exhaust Manifold Kit also relies on the enterprise’s mature pipe fitting processing technology to form product advantages of both standardization and customization. The Exhaust Manifold Kit of the same category further strengthens the adaptability of industrial-grade scenarios and can meet the exhaust system transformation needs of various industries.

I. How Does Exhaust Efficiency Affect Engine Performance?

Core Correlation Logic

- Exhaust efficiency directly determines the exhaust speed of waste gas in the engine cylinder. If the waste gas cannot be discharged quickly, it will occupy the cylinder space, resulting in insufficient filling of fresh mixture and reducing engine combustion efficiency.

- Low-efficiency exhaust will generate exhaust backpressure, increasing the working resistance of the engine, which will not only cause power and torque attenuation but also increase fuel consumption.

- A long-term high backpressure environment will aggravate the thermal load of internal engine components and affect the service life of the components.

JIATIAN’s Targeted Solutions

- JIATIAN’s Exhaust Manifold Kit adopts an optimized pipe cross-section and equal-length pipeline design, which can effectively reduce exhaust resistance and improve the overall exhaust flow rate.

- The pipeline layout of the kit has been accurately calculated, which can realize the synchronization of exhaust gas discharge from each cylinder, avoid exhaust interference between cylinders, further improve exhaust efficiency, and help the engine release potential power and torque.

II. Why Are Material and Craftsmanship Critical?

The Decisive Role of Materials in Product Performance- The exhaust manifold is in a cyclic working condition of high-temperature and corrosive exhaust gas for a long time. Ordinary gray cast iron is prone to high-temperature cracking and cannot meet the requirements of long-term stable operation.

- JIATIAN’s Exhaust Manifold Kit is made of materials such as high-silicon-molybdenum (HSM) cast iron, titanium alloy, or stainless steel. These materials have excellent thermal strength and crack resistance, can withstand high-temperature cyclic impact, and have good corrosion resistance.

The Core Guarantee of Craftsmanship for Product Quality- Relying on the pipe fitting processing experience accumulated by its predecessor, Ningbo Xingxin Metal Products Factory (founded in 1995), JIATIAN is equipped with 10 CNC fully automatic pipe bending machines, 4 fully automatic laser welders, 4 sets of welding robots and other professional equipment, which can realize high-precision forming and welding of pipelines.

- The enterprise’s water expansion bellows equipment and technology are at the industry-leading level. Some components of its Exhaust Manifold Kit adopt water expansion forming technology to ensure the structural stability and sealing of the pipeline; at the same time, the enterprise has built a comprehensive laboratory that can conduct full-process performance testing on materials and finished products to ensure that products meet working condition requirements.

Content Key Points Summary?

Core Sections Key Points Exhaust Efficiency and Engine Performance 1. Exhaust efficiency affects mixture filling and combustion efficiency 2. High backpressure leads to power attenuation and increased fuel consumption 3. Equal-length pipeline design eliminates exhaust interference and improves efficiency Importance of Materials and Craftsmanship 1. Special materials such as HSM cast iron are required for high-temperature working conditions to ensure stability 2. Processes such as laser welding and water expansion forming ensure product precision 3. The comprehensive laboratory implements full-process performance testing

Q: Will the improved exhaust efficiency of the Exhaust Manifold Kit affect the low-speed power performance of the engine?

A: No. JIATIAN’s Exhaust Manifold Kit adopts an optimized pipe cross-section and equal-length pipeline design. While improving exhaust efficiency at high speeds, it also balances exhaust backpressure in the low-speed range, ensuring the stability of the engine’s power output in the full speed range without the problem of weak low-speed power.

Q: Does the Exhaust Manifold Kit require special maintenance during daily use?

A: No special maintenance is required under normal working conditions, only regular inspection of the bolt fastening status and pipeline tightness of the kit is needed; if the vehicle is driven in dusty, highly corrosive or extreme high-temperature environments for a long time, it is recommended to check the pipeline surface for rust and cracks every 6-12 months, and heat insulation cotton or ceramic coating can be added as an option according to needs to extend the product service life.

Q: Can the Exhaust Manifold Kit adapt to the later modification needs of turbocharged engines?

A: Yes. JIATIAN’s Exhaust Manifold Kit is equipped with standardized threads and adjustable brackets, which are compatible with the subsequent installation of high-flow turbochargers and high-performance exhaust pipes. At the same time, its materials such as HSM cast iron and titanium alloy can withstand the higher exhaust temperature and pressure brought by turbocharging, and can provide a stable exhaust foundation for ECU power tuning, retaining sufficient power upgrade space.

Q: For special vehicle models, can a customized Exhaust Manifold Kit be provided?

A: Yes. JIATIAN can provide full-process customized solutions, covering from single-piece production to mass production. The enterprise has an independent R&D and processing center, which can customize the Exhaust Manifold Kit with exclusive pipeline direction and specifications according to the engine layout and exhaust interface size of special vehicle models to meet personalized or industry customization needs.

English

English