Fuel Supply Line

information to be updated

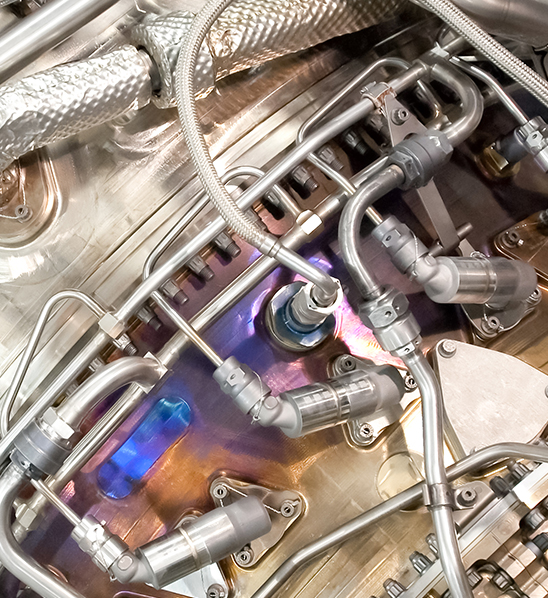

The Fuel Supply Line is a critical channel in the fuel supply system, responsible for transporting fuel from the fuel tank through components such as the pump and filter to the engine's injectors or carburetor, ensuring reliable and accurate fuel delivery. It often forms a complete fuel supply system with a fuel pump, fuel filter, and pressure regulating valve.

Product Features:

Made of materials resistant to corrosive fuels such as gasoline, diesel, ethanol/biodiesel, ensuring long service life.

It can withstand the high pressures generated by fuel system operation and the high ambient temperatures within the engine compartment, ensuring safe fuel delivery.

It utilizes a multi-layer structure or specialized material design to effectively prevent fuel vapor from escaping into the atmosphere, meeting stringent environmental and emissions regulations.

Precise connectors and mounting design ensure a tight, leak-proof connection with the fuel tank, filter, and engine injection system, ensuring driving safety.

About JIATIAN

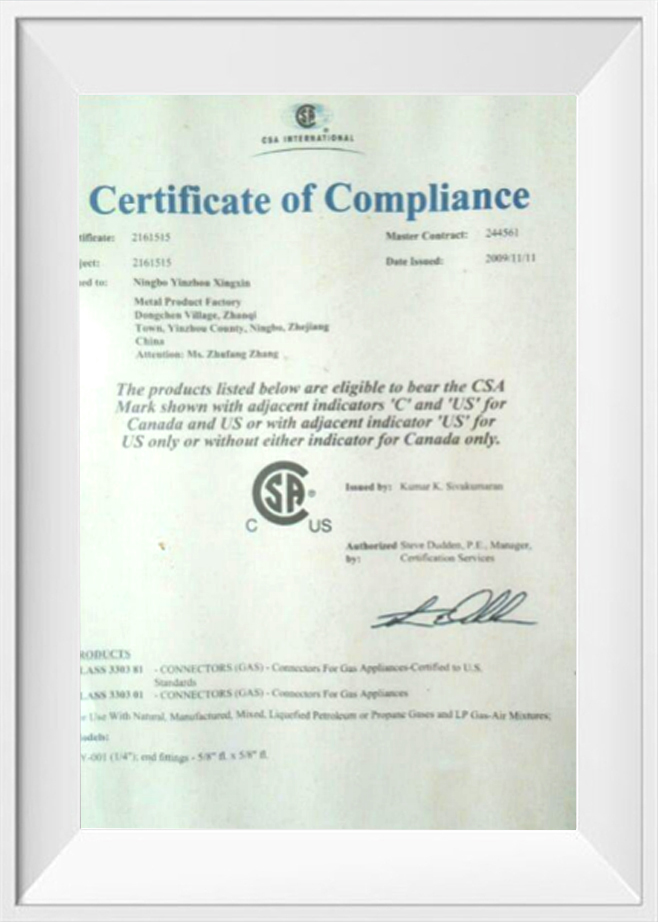

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

Is Your Diesel Engine Losing Power? A Closer Look at Fuel Delivery IssuesIf you've noticed your diesel vehicle, truck, or equipment isn't responding the way it used to, you're not alone. A gradual loss of power, a rough idle, or a sudden decrease in fuel economy can be fru...view More

Dec 15, 2025 ? Industry News

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

In automotive fuel systems, lines are not merely simple conduits for fuel delivery; they are the critical lifeline ensuring efficient, clean, and safe engine operation. With increasingly stringent emission regulations, diversification of fuel compositions (such as ethanol, biodiesel blends), and continuously rising temperatures and pressures within the engine compartment, traditional lines face severe challenges including?corrosive permeation, high-pressure bursting, evaporative emissions, and connection failures. Line failure can directly lead to power loss, excessive emissions, and even safety hazards.

Addressing these industry pain points,?JIATIAN, leveraging nearly three decades of deep expertise in automotive pipe fittings manufacturing, offers?high-tech fuel supply lines?as the core solution. Through the integration of?materials science, structural design, and precision manufacturing, we provide?reliable, environmentally friendly, and high-performance?fuel delivery assurance for vehicle and system manufacturers. Our products meet China VI and above emission standards, are compatible with various new fuels, and support the industry's shift towards higher efficiency and cleaner operation.

What is a Fuel Supply Line?

The fuel supply line is the complete delivery network connecting the fuel tank, pump, filter, pressure regulator, and finally the engine injectors or carburetor. It functions like the vehicle's "vascular system," responsible for the continuous, stable, and precise delivery of fuel to the engine's heart under complex operating conditions.

Traditional Lines vs. JIATIAN High-Performance Lines

| Comparison Dimension | Traditional / Low-Standard Lines | JIATIAN High-Performance Fuel Lines |

|---|---|---|

| Core Mission | Basic fuel delivery | Safe, precise, and environmentally compliant high-pressure fuel delivery |

| Regulatory Compliance | Meets basic emission requirements | Proactively compatible with the most stringent evaporative emission and environmental regulations like China VI, Euro 6 |

| Fuel Compatibility | Standard gasoline/diesel | Fully compatible with corrosive fuels like gasoline, diesel, ethanol, biodiesel |

| Design Philosophy | Single-function oriented | System safety and long-term reliability oriented |

Core Functions & Performance

-

Corrosion Resistance & Long-Term Durability

-

Industry Need: Modern fuel additives and alternative fuels (e.g., ethanol) are chemically corrosive to rubber, plastics, and metals, easily causing lines to age, become brittle, or clog.

-

JIATIAN Solution: Utilizes?special polymer composite materials or dual/multi-layer metal structures. The inner layer possesses exceptional chemical corrosion resistance, ensuring no performance degradation after long-term contact with various fuels, significantly extending service life.

-

-

High-Pressure & High-Temperature Resistance

-

Industry Pain Point: Direct injection engines bring higher system pressures, and engine bay ambient temperatures are extremely high, causing ordinary lines to expand, deform, or burst.

-

JIATIAN Core Technology: Lines incorporate?reinforcement layer design?(e.g., high-strength braiding), capable of withstanding system pulse pressures up to several tens of Bar and extreme temperature ranges from?-40°C to 150°C, ensuring shape and performance stability under all operating conditions, eliminating safety risks.

-

-

Ultra-Low Permeation & Environmentally Sealed

-

Regulatory Core: Stringent evaporative emission regulations require near-zero fuel vapor leakage.

-

JIATIAN Innovative Design: Employs?multi-layer barrier structures?(e.g., EVOH barrier layer) or?special low-permeability materials, effectively blocking hydrocarbon molecules from permeating the pipe wall, reducing fuel vapor emissions to extremely low levels, helping OEMs easily meet environmental regulations.

-

-

Precision Connection & System Integration

-

Safety Critical: Leakage at connection points is the most common fuel system failure.

-

JIATIAN Process Assurance: Utilizing?advanced CNC tube bending, hydraulic internal forming, laser welding, and robotic welding technologies, ensuring each pipe section and its fittings (e.g., quick-connect couplings, flanges) achieve?millimeter-level precision matching. Combined with leading proprietary processes like hydroforming for corrugated pipes, connections to components like the tank, filter, and fuel rail are guaranteed?to seal correctly on first assembly, aiming for maintenance-free service life.

-

JIATIAN Product Highlights & Brand Strength

| Highlight Dimension | Specific Manifestation | Value to Customers |

|---|---|---|

| Manufacturing Capability | 32,000㎡ site, equipped with a?full chain of high-end equipment?including 10 CNC automatic tube benders, 4 laser welders, an 800T hydraulic hydroforming machine, etc., with max processing diameter up to ¢80. | Stable supply capacity for large-volume, high-consistency, complex-shaped pipes. |

| Technical Leadership | Industry-leading hydroforming technology and equipment for corrugated pipes, supported by in-house R&D center and comprehensive laboratory. | Access to?innovative line solutions with superior structure, higher strength, and lighter weight, enhancing vehicle performance. |

| Quality Control | Full-process in-house processing and inspection?from raw material to finished product, utilizing large machining centers and welding robots to ensure process consistency. | Every line delivers exceptional reliability and safety, reducing vehicle failure rates and after-sales risks. |

| Legacy & Experience | Originating from Ningbo Xingxin Metal Products Factory established in 1995, with?nearly 30 years of focus on automotive pipe fittings manufacturing. | Deep understanding of industry trends, material evolution, and process challenges, positioning us as a?trustworthy long-term partner. |

Our Mission: Committed to creating?world-leading automotive bellows and line systems with outstanding quality and innovative technology, ensuring each product performs excellently in all environments and promoting industry progress.

Frequently Asked Questions (FAQ)

Q1: Are your fuel lines suitable for ethanol-blended gasoline (e.g., E10) or high-percentage biodiesel?

A:?Absolutely. Our lines undergo comprehensive material selection and structural design phases, including thorough compatibility testing and validation for various corrosive modern fuels. This ensures no performance degradation or failure occurs due to the chemical properties of the fuel during long-term use.

Q2: How do you ensure line reliability in high-pressure direct injection systems?

A:?We guarantee this through two aspects: First,?Material & Structure?– using multi-layer reinforcement designs to ensure burst pressure far exceeds the system's maximum operating pressure. Second,?Process & Testing?– employing advanced forming/welding processes and a complete laboratory for full endurance tests like pulse pressure, burst pressure, and fatigue strength. Products are only released after passing all data benchmarks.

Q3: What specific measures do you take to meet evaporative emission regulations?

A:?We primarily utilize?multi-layer co-extrusion technology?or?integrated ultra-low permeability barrier layers. This structure acts like a "permeation barrier wall," reducing fuel vapor permeation rates to less than one percent of traditional single-layer materials. This effectively helps the complete vehicle system meet the strictest evaporative emission limits like China VI.

Q4: We require lines with complex shapes and high precision. Can JIATIAN achieve this?

A:?This is one of our core strengths. We possess?full-chain, high-precision manufacturing capabilities from CNC precision bending and hydraulic internal forming to laser welding, with a maximum processing length of 1.5 meters and support for complex 3D routing. Combined with collaborative design from our in-house R&D center, we can provide a one-stop, high-precision solution from blueprint to finished product.

English

English