Exhaust Up Pipe

Exhaust Up Pipe

Exhaust Up Pipe

information to be updated

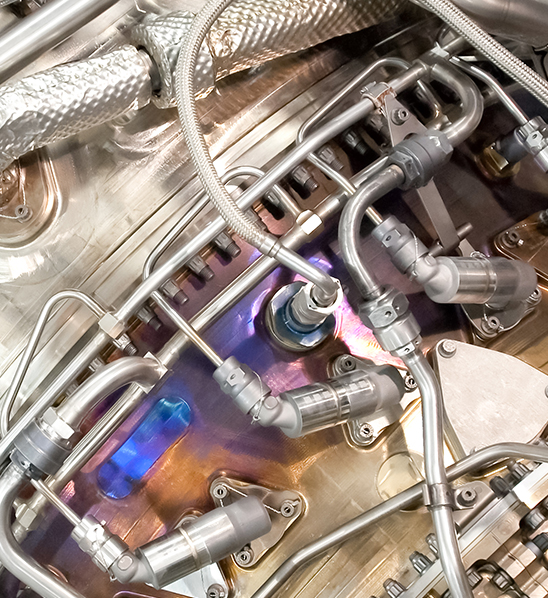

The exhaust manifold is a key component that connects the engine's cylinder head exhaust ports to the exhaust system. It collects high-temperature, high-pressure exhaust gases from each cylinder after combustion and directs them to the exhaust pipe, catalytic converter, and muffler.

Core Functions:

Exhaust Gas Collection: Efficiently channels the pulsed exhaust gases from multiple cylinders into a single or limited number of outlets.

Pulse Coordination: Through precise piping design, it minimizes interference between exhaust gases from each cylinder, ensuring smooth exhaust discharge.

Performance Enhancement: Optimized flow path design reduces exhaust backpressure, thereby increasing the engine's volumetric efficiency and power output.

Thermal Management and Emissions: Withstands and manages temperatures up to 1000°C and provides the necessary heat for the close-coupled catalytic converters in modern vehicles.

About JIATIAN

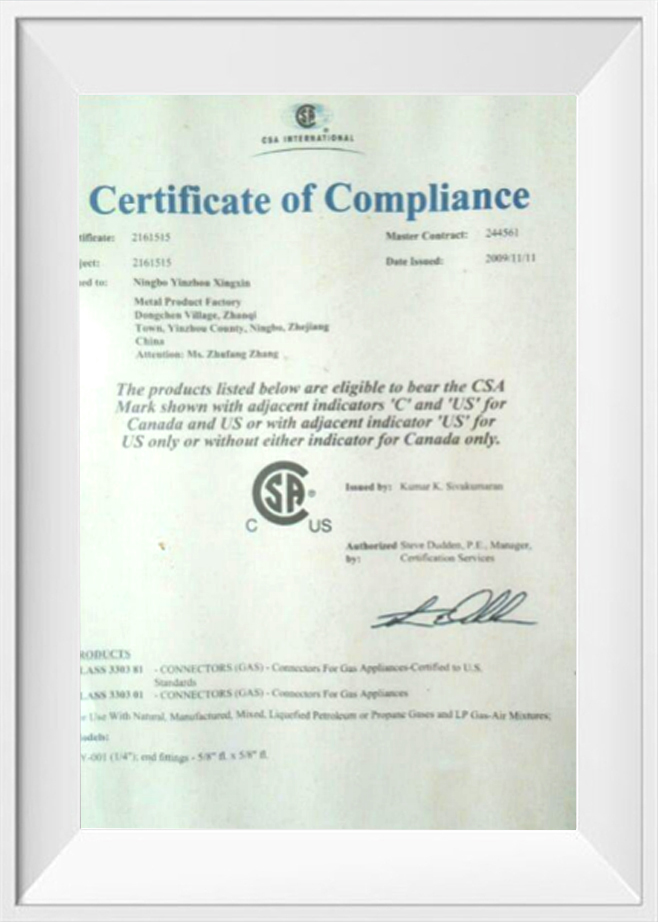

The company is located in Wanhou, Zhanqi Town, Yinzhou District, Ningbo City. It is 25 kilometers away from Ningbo Liushi Airport and 5 kilometers away from Ningbo Coastal Industrial Zone. The surrounding area is beautiful with convenient transportation. The company was established on the basis of the development of Ningbo Xingxin Metal Products Factory (established in 1995), and is a high-tech enterprise specializing in the production of automotive pipe fittings. The company's area is 32,000 square meters; the factory area is 26,000 square meters.

The main products of the company are: manufacturing and development of automotive corrugated pipes. Currently, there are 10 CNC fully automatic pipe bending machines, 2 large-scale brazing furnaces assembly lines, 10 various specifications hydraulic internal forming machines (with the maximum processing length of 1.5 meters and diameters ranging from ¢10 to ¢80), 1 800T hydraulic water expansion machine, 4 fully automatic laser welders, 4 sets of welding robots, 8 large-scale machining centers, 6 Panasonic arc welding machines, and over 30 various supporting pipe forming machines. The company has its own R&D and processing centers. The water expansion corrugated pipe equipment and technology of the company are currently at the industry leading level. A comprehensive laboratory has been established.

The company is committed to creating the world's leading automotive bellows with outstanding quality and innovative technology, ensuring that each product can perform well in various environments and promoting the progress of the industry.

News and Information

-

Is Your Diesel Engine Losing Power? A Closer Look at Fuel Delivery IssuesIf you've noticed your diesel vehicle, truck, or equipment isn't responding the way it used to, you're not alone. A gradual loss of power, a rough idle, or a sudden decrease in fuel economy can be fru...view More

Dec 15, 2025 ? Industry News

-

How Does a Faulty EGR Pipe Affect My Car's Performance?It’s a scenario many drivers have experienced. You’re driving along, and suddenly, your trusted vehicle feels different. Maybe the check engine light flickers on, or you notice a rough idle when you’r...view More

Dec 08, 2025 ? Industry News

-

A clever solution to the truck's exhaust brake problemAbstract: Frequent use of the exhaust brake makes it difficult to damage the headstock. This is a common problem for many truck drivers. I consulted with experienced drivers, and some believe that the...view More

Oct 27, 2025 ? Industry News

-

The exhaust pipe is black, what's going on?Summary: I believe many car enthusiasts have experienced this: Why is the exhaust pipe white? What should I do if it's white? Is it a sign of a car problem? Recently […] I believe many car enthusiasts...view More

Oct 27, 2025 ? Industry News

-

Car modification knowledge: the benefits of changing the exhaust manifoldAbstract: The exhaust manifold is a key component that collects exhaust gases from all engine cylinders and discharges them out of the vehicle. The efficiency of the entire exhaust system depends on i...view More

Oct 27, 2025 ? Industry News

-

Introduction to Automobile Oil Return PipeAbstract: The function of a vehicle's oil return line: It allows excess oil to return to the tank, reducing fuel consumption. Not all vehicles have an oil return line. Return Line Filter […] The funct...view More

Oct 27, 2025 ? Industry News

I. Product Commonalities and Core Values

II. Product Principles of Exhaust Up Pipe

-

Exhaust Gas Collection and Diversion Principle Based on fluid mechanics principles, the Exhaust Up Pipe integrates pulsed exhaust gas from multiple engine cylinders into a single or a small number of outlets through a multi-manifold confluence structure. Its pipeline curvature and gradual diameter change design reduce turbulence loss during exhaust gas confluence. JIATIAN uses hydraulic internal forming machines with a maximum processing length of 1.5 meters and a diameter range of ¢10 to ¢80 to accurately realize the flow channel optimization forming of the pipeline.

-

Pulse Coordination Principle There is a timing difference in exhaust from different cylinders. The Exhaust Up Pipe offsets the mutual interference of exhaust pulses through unequal-length pipeline design, avoiding a decrease in engine intake efficiency caused by exhaust gas backflow. JIATIAN's 800T hydraulic water expansion machine can achieve one-time forming of special-shaped pipeline structures, ensuring the precise implementation of the pulse coordination design.

-

Thermal Management and Emission Adaptation Principle The Exhaust Up Pipe must withstand high temperatures of up to 1000°C and provide the necessary operating temperature for close-coupled catalytic converters. It is made of high-temperature-resistant stainless steel. JIATIAN's large-scale brazing furnace assembly lines can realize overall high-temperature brazing treatment of pipe fittings, enhancing the product's heat resistance and sealing performance. At the same time, the supporting comprehensive laboratory can conduct full-process testing of the product's thermal stability.

III. Typical Application Cases

-

Passenger Vehicle Fuel Power System Suitable for 1.5T-2.0T household passenger vehicles, the Exhaust Up Pipe produced by JIATIAN can effectively reduce the exhaust backpressure of small-displacement turbocharged engines and improve engine torque at medium and low speeds. It has been matched with compact SUV models of many domestic independent brand passenger vehicle manufacturers, and its laser-welded pipeline interfaces can achieve sealing reliability for more than 5 years.

-

Commercial Vehicle Diesel Power System For large-displacement engines of heavy-duty diesel trucks, the large-diameter Exhaust Up Pipe processed by JIATIAN's hydraulic internal forming machines can meet the diversion demand of high exhaust gas flow and withstand higher exhaust temperatures of diesel engines. It has been applied to heavy-duty tractor series of domestic commercial vehicle manufacturers.

-

Hybrid Vehicle Exhaust System Adapting to the engine start-stop working conditions of plug-in hybrid vehicles, the Exhaust Up Pipe needs to have rapid warm-up capability to ensure the efficient operation of the catalytic converter. JIATIAN's water expansion forming technology can realize uniform thin-wall forming of pipelines, improving heat transfer efficiency, and has been matched with special exhaust systems for hybrid vehicles.

IV. Detailed Comparison of Exhaust Up Pipes with Different Processes/Materials

|

Comparison Dimension |

Traditional Stamped Exhaust Up Pipe | JIATIAN Water Expansion Forming Exhaust Up Pipe | Cast Iron Exhaust Up Pipe | Stainless Steel Exhaust Up Pipe (JIATIAN's Main Product) |

|---|---|---|---|---|

| Flow Channel Precision | Medium, with turbulence points at stamping joints | High precision, seamless and smooth flow channel | Low, rough inner wall | High, uniform inner wall forming |

| High-Temperature Resistance | Resistant to below 800°C | Resistant to continuous high temperature of 1000°C | Resistant to around 900°C | Resistant to above 1000°C |

| Weight | Medium | Lightweight, 15%-20% lighter than traditional models | Heavy, 30% heavier than stainless steel models | Lightweight, suitable for vehicle weight reduction needs |

| Welding Sealing Performance | Multiple joints, prone to leakage risks | Laser/robot welding, 99.9% sealing rate | Integrally cast without joints but easy to crack | Few welding points, excellent sealing performance |

| Application Scenarios | Economical household vehicles | Mid-to-high-end passenger vehicles/hybrid vehicles | Old commercial vehicles | Passenger vehicles/commercial vehicles/hybrid vehicles |

| JIATIAN Production Capacity Support | - | Supported by more than 30 pipe forming equipment for large-scale mass production | - | Supported by brazing furnace assembly lines for batch stable supply |

V. Maintenance Guidelines for Exhaust Up Pipe

-

Daily Inspection

- Regularly inspect the pipeline interface welds of the Exhaust Up Pipe for rust or abnormal noise caused by exhaust gas leakage. Refer to the leakage detection standards of JIATIAN's comprehensive laboratory to check for sealing hidden dangers through pressure testing;

- Check whether the heat insulation layer on the pipeline surface is intact. If damaged, replace it in time to avoid high-temperature radiation affecting surrounding components.

-

Regular Maintenance

- Clean the carbon deposits on the inner wall of the pipeline every 20,000 kilometers. Excessive carbon deposits will increase exhaust backpressure. Use special high-temperature carbon remover for cleaning to avoid damaging the pipeline coating;

- Recheck the torque of the welding interfaces every 50,000 kilometers and calibrate them according to the installation torque parameters provided by JIATIAN (different models correspond to different torque values) to prevent interface loosening.

-

Fault Handling

- If there is exhaust abnormal noise, first check whether the Exhaust Up Pipe pipeline is cracked. Cracked cast iron pipe fittings need to be replaced as a whole, while JIATIAN's stainless steel pipe fittings can be repaired by laser welding;

- If the exhaust backpressure increases abnormally, check whether the pipeline is deformed or blocked. JIATIAN's R&D center can be relied on for flow channel testing and repair plan formulation.

VI. Frequently Asked Questions (FAQ)

-

Q: How to confirm the compatibility of Exhaust Up Pipe? A: It is necessary to confirm based on the number of engine cylinders, exhaust manifold interface specifications, and vehicle chassis layout. JIATIAN can provide customized compatibility solutions based on vehicle models, and its 10 CNC pipe bending machines can achieve precise customization of pipelines for different vehicle models.

-

Q: What is the warranty period of Exhaust Up Pipe produced by JIATIAN? A: Depending on the application scenario of the product, the warranty period covers 1-3 years. The warranty standards for its welding interfaces and forming structures are higher than the industry's conventional level. For details, refer to the vehicle warranty manual.

- Q: Will the material of Exhaust Up Pipe affect vehicle emissions? A: It will have a direct impact. The stainless steel material adopted by JIATIAN can ensure the long-term corrosion resistance of the pipeline, avoid exhaust gas leakage and emission exceeding standards caused by pipeline corrosion, and its precise flow channel design can improve the working efficiency of the catalytic converter.

English

English